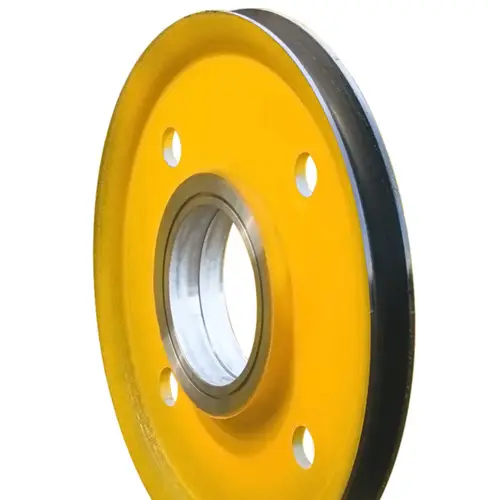

China OEM Pulley with Fixed Shackle, Special Type

The China OEM Pulley with Fixed Shackle is a specialized and high-quality product designed for various industrial applications. With its unique features and exceptional performance, it is an ideal choice for professionals seeking reliable and efficient air compressor parts. Manufactured by a professional and experienced manufacturer, this pulley is guaranteed to meet the highest standards of quality and durability.

Product Description

1. Versatile Design

The China OEM Pulley with Fixed Shackle is available in various models, including single swivel pulley, fixed ring pulley, and double fixed/swivel pulley. It is crafted with precision using high-quality materials such as zinc alloy and carbon steel. The pulley’s surface can be galvanized, nickel plated, or made with stainless steel 316 or 304, ensuring excellent corrosion resistance.

2. Quality Assurance

With over 30 years of experience in manufacturing and exporting shackles, our company takes pride in delivering superior products. We specialize in manufacturing single and double swivel or fixed pulleys. Our products are highly regarded and exported to European countries, USA, Canada, Australia, Japan, Korea, Singapore, and more. We have full control over the production process, ensuring the highest standards of quality and performance.

3. Service Assurance

Customer satisfaction is our top priority. We offer free samples upon request, allowing you to experience the exceptional quality of our pulleys firsthand. Additionally, we are open to designated inspections, ensuring transparency and reliability. Our dedicated team is committed to providing prompt and efficient customer service, with all inquiries being answered within 4 hours. We look forward to establishing fruitful and long-term partnerships with our valued customers.

Our company is not only a leading manufacturer of pulleys but also supplies a wide range of industrial products. Our extensive product line includes agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, planetary gearboxes, timing pulleys, bushings, and more. We take pride in offering high-quality products at competitive prices, along with unparalleled customer service. Customization options are available for drawings and samples, ensuring that our products precisely meet your unique requirements.

Frequently Asked Questions (FAQs)

1. What materials are used in manufacturing the China OEM Pulley with Fixed Shackle?

The China OEM Pulley with Fixed Shackle is crafted with precision using high-quality materials such as zinc alloy and carbon steel. The surface can be galvanized, nickel plated, or made with stainless steel 316 or 304 for excellent corrosion resistance.

2. Where are these pulleys primarily exported?

Our pulleys are mainly exported to European countries, USA, Canada, Australia, Japan, Korea, Singapore, and more. We have established a strong presence in these markets due to our exceptional product quality and reliable performance.

3. Can I request samples of the China OEM Pulley with Fixed Shackle?

Yes, we provide free samples upon request. We believe in the quality of our products and want our customers to experience their superior performance firsthand.

4. Do you offer customization options for the pulleys?

Yes, we welcome customization requests for drawings and samples. Our dedicated team will work closely with you to ensure that our pulleys meet your specific requirements.

5. What other products does your company supply?

In addition to pulleys, our company supplies a wide range of industrial products such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, planetary gearboxes, timing pulleys, bushings, and more. We strive to offer a comprehensive solution for all your industrial needs.

All the content of this page is from the Internet, the content is only as a reference for product selection, our products are replacement parts and not original spare parts; we are not the holder of the original trademarks of the content, our products are only suitable for after-sales replacement parts and not original spare parts, our replacement parts can be perfectly adapted to the original spare parts; if you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.

Performance Characteristics of Fixed Pulley

The fixed pulley is a simple machine that is commonly used to transfer force and move objects. It has several performance characteristics that make it a valuable component in many fields.

- Efficiency: Fixed pulleys have a high level of efficiency, meaning that the input force is almost equal to the output force.

- Strength: Fixed pulleys are typically made of durable materials, such as steel or aluminum, and can withstand heavy loads.

- Flexibility: Fixed pulleys can be used in various applications and can be incorporated into different systems.

- Cost-Effective: Fixed pulleys are generally less expensive than other types of pulleys, making them a cost-effective solution for many applications.

Types and Characteristics of Fixed Pulley

Fixed pulleys can come in different types based on their design and construction. Single fixed pulleys have only one wheel and are often used to change the direction of a force. Double fixed pulleys have two wheels and can increase the mechanical advantage of a system. Triple fixed pulleys have three wheels and can further increase mechanical advantage.

The materials used to make fixed pulleys can also affect their characteristics. Steel pulleys are strong and durable, making them ideal for heavy-duty applications. Aluminum pulleys are lightweight and corrosion-resistant, making them suitable for outdoor use.

Advantages of Fixed Pulleys Made of Different Materials

Fixed pulleys can be made of various materials, each with its own advantages. Steel pulleys are strong and durable, making them ideal for heavy-duty applications. They can withstand high loads and are less prone to wear and tear.

Aluminum pulleys are lightweight and corrosion-resistant, making them suitable for outdoor use. They are also easy to install and require less maintenance.

Plastic pulleys are lightweight and affordable, making them ideal for smaller applications. They can also be used in wet environments, as they are resistant to corrosion.

Application of Fixed Pulley

Fixed pulleys can be found in various fields, including Mechanical Advantage Systems, Exercise Equipment, Home Improvement, Agriculture, Household Applications, and more. In Mechanical Advantage Systems, fixed pulleys can be used to lift heavy loads with less effort. In Exercise Equipment, fixed pulleys can be used to train the muscles and improve strength. In Home Improvement, fixed pulleys can be used to move heavy objects or lift materials to higher floors. In Agriculture, fixed pulleys can be used to raise and lower farm equipment. In Household Applications, fixed pulleys can be used for DIY projects and repairs.

Future Development Trends and Opportunities

The fixed pulley market is expected to grow in the coming years, driven by the increasing demand for affordable and efficient mechanical solutions. There is also a growing trend towards sustainability and eco-friendliness, which could create opportunities for manufacturers to produce pulleys made from renewable or recycled materials. Additionally, the rise of e-commerce and online marketplaces could make it easier for consumers to find and purchase fixed pulleys.

How to Choose a Suitable Fixed Pulley

When choosing a fixed pulley, several factors should be considered, including load capacity, material, diameter and size, type of pulley, and bore size.

Load capacity refers to the maximum weight that the pulley can support. It is important to choose a pulley with a load capacity that is greater than the weight of the object being lifted.

The material of the pulley can affect its strength, durability, and corrosion resistance. Steel is a strong and durable material, while aluminum is lightweight and corrosion-resistant.

The diameter and size of the pulley can affect its efficiency and the amount of force required to move an object. Smaller pulleys require less force but have a lower mechanical advantage. Larger pulleys require more force but have a higher mechanical advantage.

The type of pulley can also affect its application. Single pulleys are ideal for changing the direction of a force, while double and triple pulleys are better suited for increasing mechanical advantage.

The bore size of the pulley refers to the diameter of the hole in the center of the wheel. It is important to choose a pulley with a bore size that matches the diameter of the shaft it will be mounted on.

Summary

Fixed pulleys are an essential component in various fields, including Mechanical Advantage Systems, Exercise Equipment, Home Improvement, Agriculture, and Household Applications. They have several performance characteristics, including high efficiency, strength, flexibility, and cost-effectiveness. Fixed pulleys can be made of different materials, each with its own advantages. When choosing a fixed pulley, several factors should be considered, such as load capacity, material, diameter and size, type of pulley, and bore size. The future development of fixed pulleys is expected to be driven by the increasing demand for affordable and eco-friendly mechanical solutions.

Author: Dream